INTRO — Why We Show Our Process

Most brands never show how their products are made.

We do — because JockTribe isn’t producing generic soft rubber toys.

We build body-safe, platinum silicone tools, engineered with the same seriousness you’d expect from medical or high-performance products.

Every curve, every texture, every layer is intentional.

And every step takes time — real time — because shortcuts don’t create quality.

Below is the complete manufacturing journey of a JockTribe dildo, with real numbers, so you can see the craft behind the pleasure.

Design Based on Real Bodies & Real Feedback

We start from anatomy + user experience, not guesswork.

*Design cycle: 4–6 weeks

*Based on user feedback, competitor flaws, and comfort angles

*3D sculpting → prototype → test round

*1–2 internal iterations before mold creation

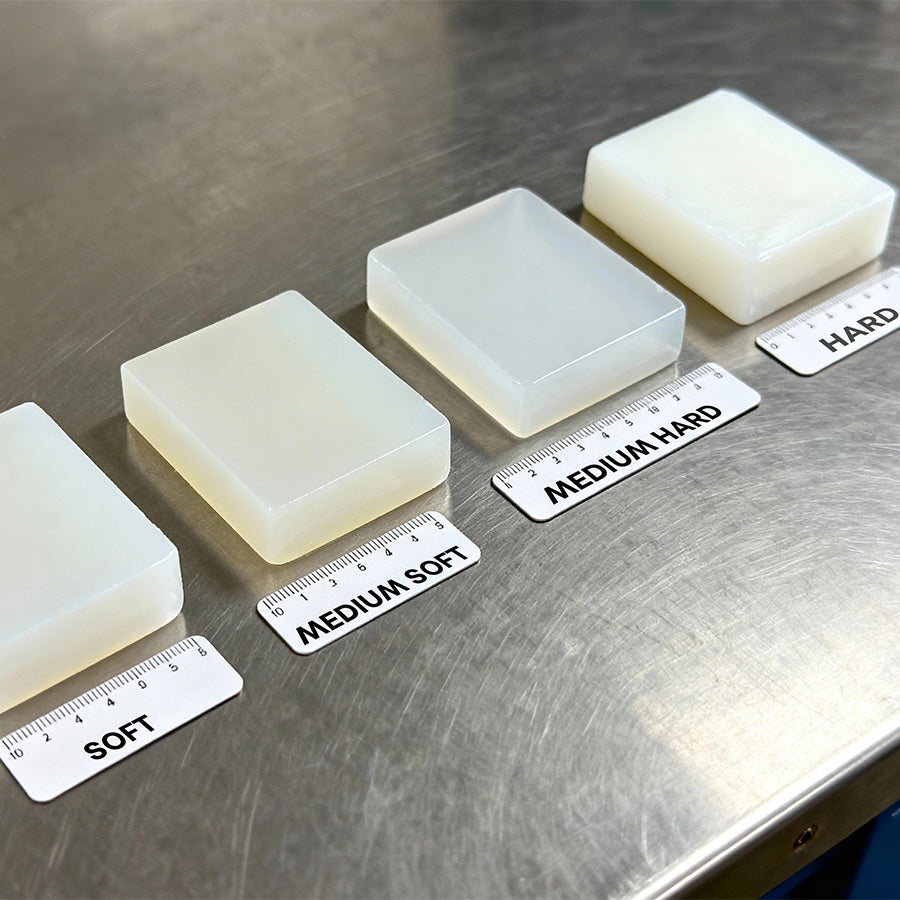

Platinum Silicone Material Selection

Only medical-aligned platinum silicone, never TPE.

*Matches FDA 21 CFR 177.2600 & ISO 10993 standards

*Core & skin use different Shore hardness

*Material tuning time: 3–7 days

Metal Mold Engineering (Precision Tooling)

Precision tooling for realism, consistency, and durability.

*Mold development: 3–6 weeks

*CNC machining, polishing, airflow venting

*High cost but allows sharp details & long mold life

*Required for double-layer casting

Silicone Mixing & Vacuum Degassing

Zero bubbles. Zero guesswork.

*A/B components + safe pigments

*Vacuum process: 10–20 min

*Total batch prep: 20–35 min

Double-Layer Casting (JockTribe Signature Technology)

Firm core + soft skin = the JockTribe feel. See how this affects real-world performance in our Firmness Guide.

Inner Core

*Harder silicone

*Pre-curing: 30–60 min

Outer Skin

*Ultra-soft silicone

*Wraps the semi-cured core

*Pouring + balancing: 10–20 min

Total casting cycle:40–90 min

Thermal Curing (Solidifying the Shape)

Strength and durability come from time, not shortcuts.

*Oven cure: 1–3 hours

*Cooling: 1–3 hours

*Full-strength cure: 24 hours

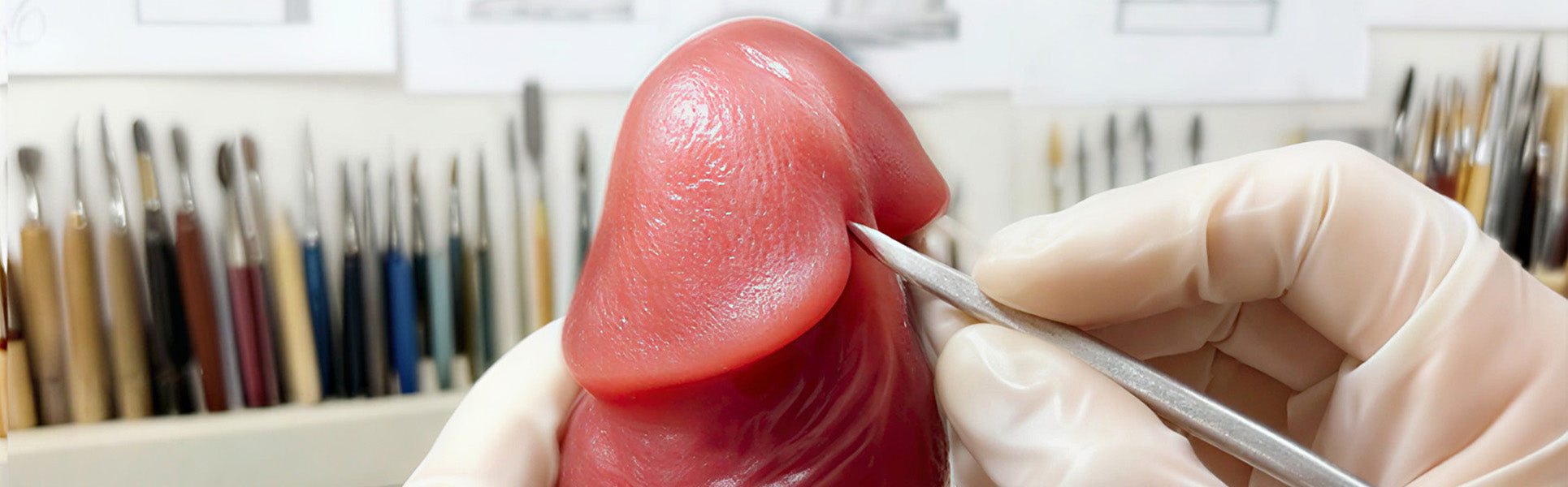

Demolding, Hand-Trimming & Surface Finishing

Every piece is finished by human hands, not by machines.

*Seam trimming, smoothing, texture refinement

*Time per piece: 20–40 min

*Precision work ensures comfortable contact zones.

What this means for you: better comfort, better control, and a product that feels intentional — not mass-produced.

Precision work ensures comfortable contact zones — especially when paired with the right fit from our

Size Guide.

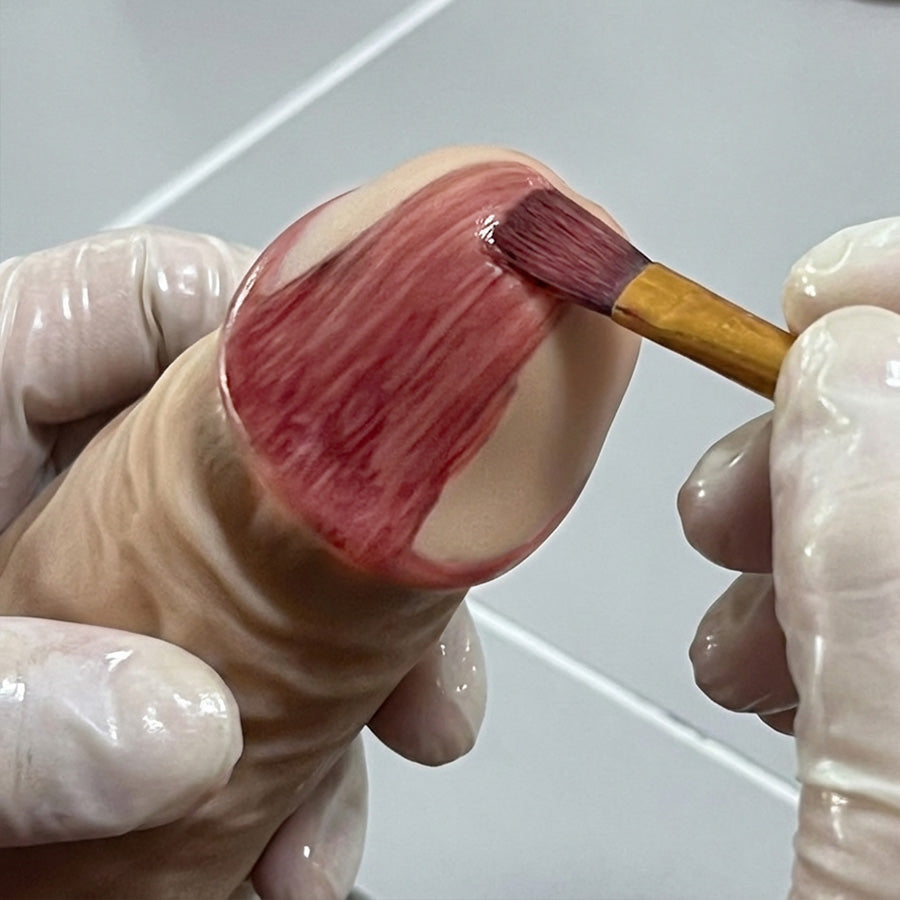

Hand-Applied Coloring (Realistic Finish)

The life-like tones are applied like art.

*Color mixing: 10–20 min/batch

*Layered hand-coloring: 20–40 min

*Curing topcoat: 30–60 min

Washing, Drying & Final Quality Inspection

Every piece goes through six quality checks.

*Warm wash: 10–20 min/batch

*Drying: 30–60 min/batch

*Individual QC: 3–5 min per piece

Safety Coding & Batch Traceability

Every product can be traced from raw material to hand-finisher.

*Batch ID, operator code, QC record

*Total admin time: 5–10 min/batch

Ackaging & Shipping

Clean, safe, anonymous.

*Inner protective bag: 3–5 min/item

*Order packing: 5–10 min/order

*No branding, no product description, 100% discreet packaging

See delivery timelines in our Shipping & Sales Policy.

Final Comparison — JockTribe vs Low-End Toys

A clear look at how much more goes into crafting a JockTribe piece.

| Stage | JockTribe | Low-End Toys |

|---|---|---|

| Design | 4–6 weeks of user feedback analysis, anatomical engineering & multiple prototypes. | 1–2 days copying existing shapes with no user testing. |

| Mold | Precision metal molds, 3–6 weeks of CAD, CNC machining & polishing. | Cheap silicone molds, often reused and made within days. |

| Casting | Double-layer platinum silicone: firm inner core + soft outer skin. | Single-layer casting using unknown materials. |

| Curing | 2–6 hour temperature-controlled cure + ≈24h full-strength cure. | Fast cure cycle with inconsistent hardness. |

| Finishing | 20–40 min hand trimming, edge smoothing & texture refinement. | Minimal trimming, visible seams, rough surfaces. |

| Coloring | 20–40 min hand coloring with layered, realistic tones. | Flat single-color finish, no realism. |

| Traceability | Full material batch code, date, operator & QC record. | No tracking; quality varies per batch. |

| Safety | Processes aligned with food-grade & medical-grade silicone handling. | Material sources & safety data rarely disclosed. |

Design

JockTribe: 4–6 weeks of real-user feedback, anatomical design & multiple prototypes.

Low-End: 1–2 days copying existing shapes.

Mold

JockTribe: Precision metal molds requiring 3–6 weeks of engineering.

Low-End: Cheap silicone molds made in days.

Casting

JockTribe: Double-layer platinum silicone (core + skin).

Low-End: Single-layer low-grade material.

Curing

JockTribe: 2–6h controlled curing + 24h full cure.

Low-End: Rushed curing cycle.

Finishing

JockTribe: 20–40 min of hand finishing.

Low-End: Minimal trimming, rough seams.

Coloring

JockTribe: 20–40 min hand-applied realism.

Low-End: No realistic coloring.

Traceability

JockTribe: Full batch ID system.

Low-End: No traceability.

Safety

JockTribe: Food-grade & medical-aligned processes.

Low-End: Unverified materials.